Mastering the Art of Valves and Controls: A Comprehensive Guide

In the world of industrial processes and systems, the role of valves and controls is paramount. These components serve as the gatekeepers of fluid and gas flow, regulating and controlling the movement and direction of materials within intricate networks. Valworx stands out as a trusted source in this realm, holding the prestigious ISO 9001 certification as a supplier of actuated valves and controls. Their dedication to quality and efficiency is evident in the vast array of automated valve assemblies they offer, which are meticulously built, rigorously tested, and promptly shipped to cater to the diverse needs of industrial, institutional, and government sectors.

Types of Valves and Controls

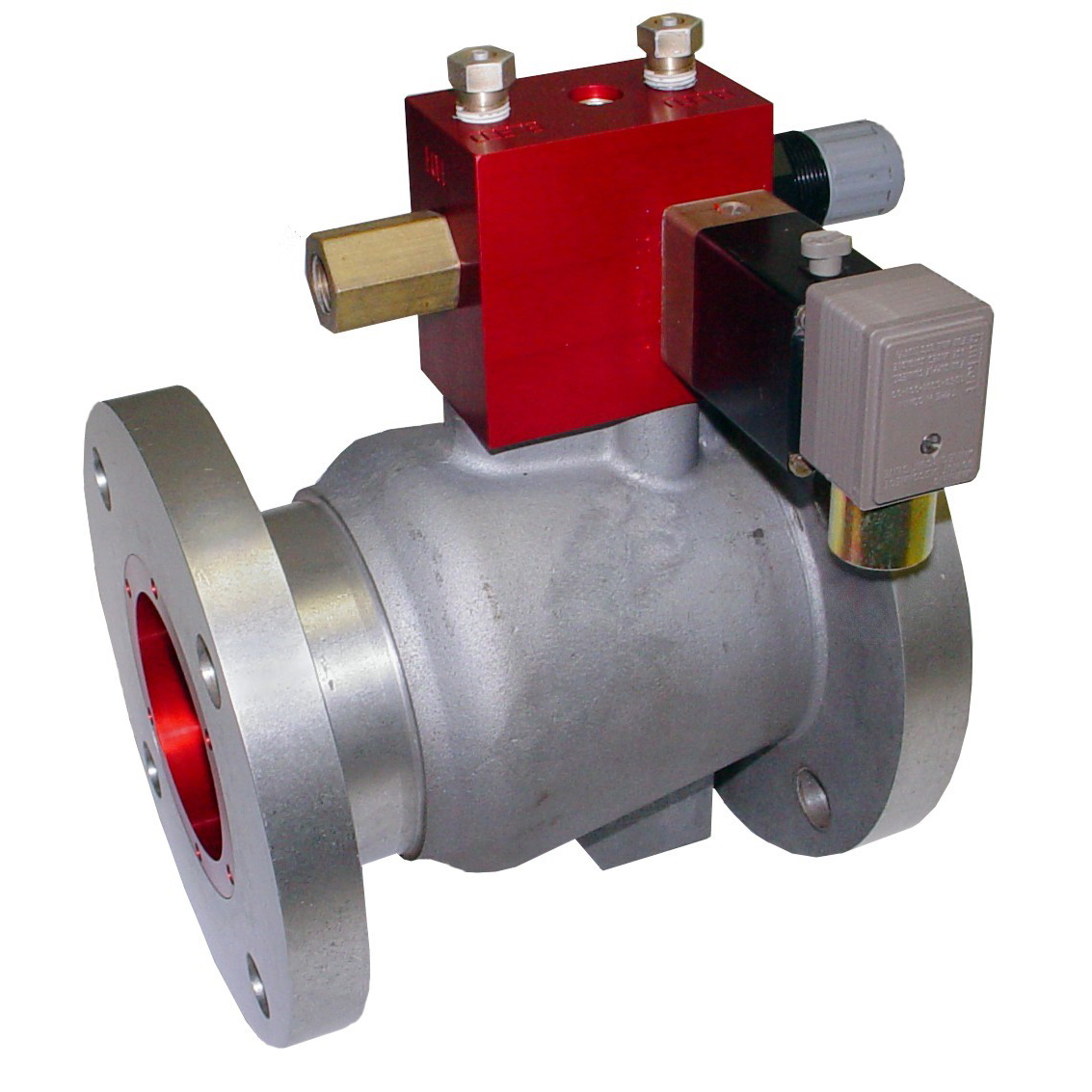

In the world of valves and controls, there are several key types that serve various functions. One common type is the ball valve, which uses a spherical closure unit to allow or stop flow. Another essential type is the butterfly valve, known for its quarter-turn operation and versatility in controlling flow. Additionally, the gate valve, with its wedge-shaped gate, is commonly used in applications where a tight shut-off is required.

Moving on, we have the globe valve, which is recognized for its precise throttling capabilities and good shut-off properties. Similarly, the check valve plays a crucial role in preventing backflow by allowing flow in one direction. Furthermore, the pressure relief valve is vital for protecting systems against overpressure by releasing excess pressure to maintain optimal operational conditions.

Another significant type is the control valve, which is integral in regulating flow, pressure, temperature, and other process variables. Control valves come in various styles such as globe, butterfly, and ball valves, each designed for specific applications. Moreover, solenoid valves are widely used for their quick response and ability to control the flow of liquids or gases in a system.

Benefits of Utilizing Actuated Valves

Actuated valves provide efficient automation solutions for various industries, allowing for precise control over fluid flow and pressure. This automation reduces the need for manual adjustments, saving time and minimizing human errors in valve operation.

Valworx’s actuated valves offer reliable performance and consistently meet industry standards, ensuring smooth operation in critical applications. This reliability translates to improved safety, as these valves function accurately even in challenging environments, providing peace of mind to operators and maintenance personnel.

By incorporating actuated valves into their systems, businesses can enhance overall productivity and efficiency. The quick response times of these valves enable rapid adjustments, optimizing process control and ultimately leading to cost savings over time.

Resilient seated butterfly valve for wastewater treatment

Valworx’s Process for Building Automated Valve Assemblies

To ensure top-notch quality and efficiency, Valworx follows a meticulous process when assembling automated valve systems. It all starts with a thorough assessment of the client’s requirements and specifications. Our experienced team works closely with customers to understand their needs, enabling us to recommend the most suitable valve assembly components for their applications.

Once the design phase is complete, our skilled technicians embark on the assembly process. Each component is carefully inspected to guarantee precision and optimal functionality. Valworx’s commitment to excellence means that all valve assemblies undergo rigorous testing procedures to verify performance and reliability. This meticulous approach ensures that our automated valve systems meet the highest standards before they are shipped to our valued industrial, institutional, and government clients.

As an ISO 9001-certified supplier, quality control is at the core of everything we do at Valworx. Our dedicated team adheres to stringent guidelines throughout the assembly process, from component selection to final testing. With a focus on consistency and attention to detail, we take pride in delivering flawlessly built automated valve assemblies that meet the diverse needs of our customers across various sectors.