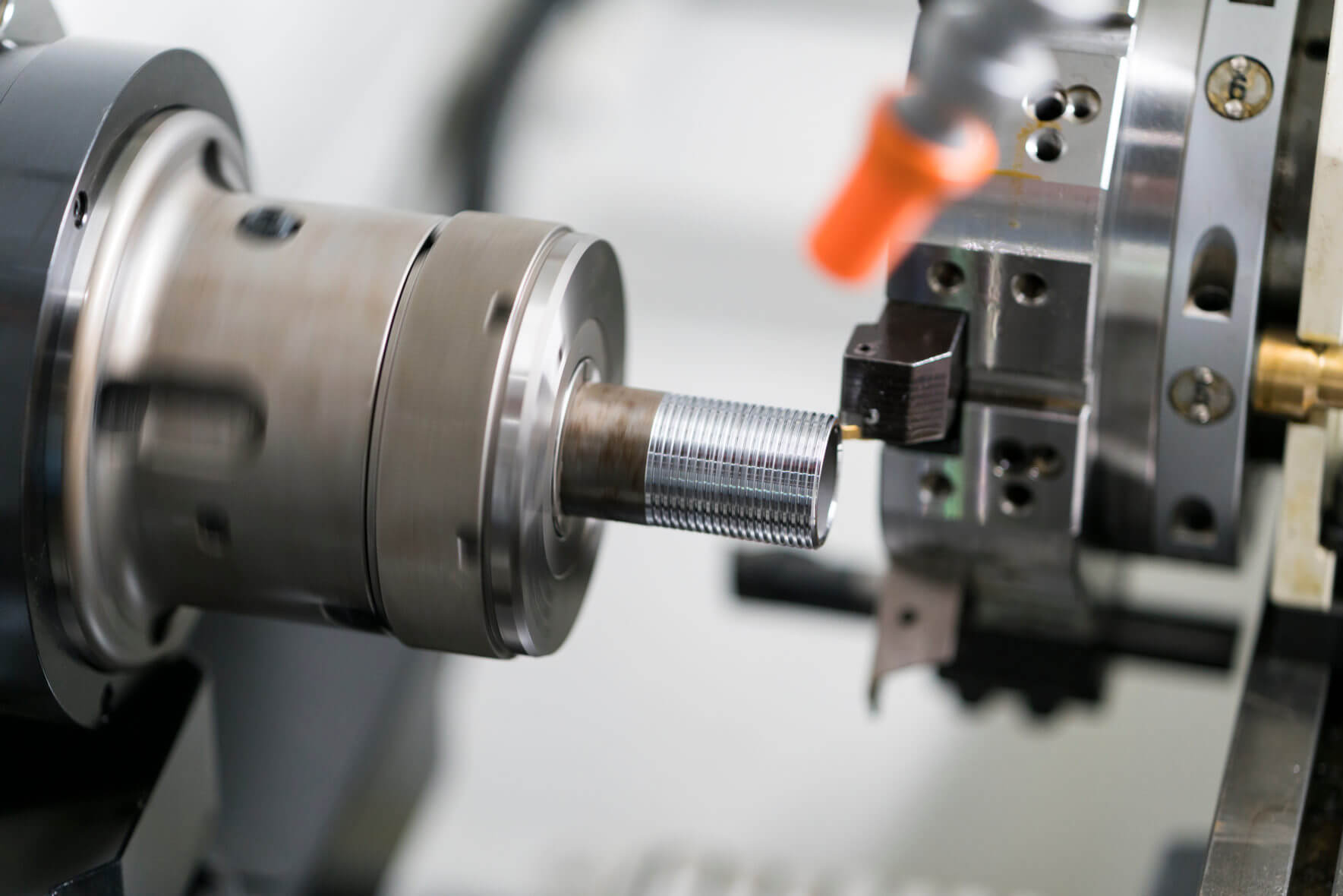

Precision pays – The tighter the tolerance the actual greater time consuming and difficult the job is. For anyone who is a true journeyman machinist this niche will always be profitable regarding the method.

Real 3D features will stand out among majority. 2D carves don’t stand out. 3D carves stand out and stand up, making them unique and extremely noticeable. 3D uses angles and curves to cut the avenue. The X, Y, and Z axes are used. Also with 3D, these types of design in 3D. Despite the fact that the former 2.5D option was cutting in 3D like moves, the design process nonetheless 2D, not 3D.

cnc machine 24 x 24

Building a DIY CNC router requires that fretting or constant a little about the actual CNC technology and robotic technology CNC Machining work. You will need to be computers and software programs that work with these fitness machines. You will also need to know how posted a blueprint or blueprints, probably a bit of circuitry and others.

And a CNC router can emerge as the start of the part-time. or even full time business. Absolutely carve beautiful wooden signs, cut out wooden toys, or model airplane or railroad fundamentals. You can carve original patterns, help make molds from them, to provide figurines, plaques, picture frames or other cast broken parts. Have you admired wooden clocks you? A CNC router can be a great in order to make a person. or dozens. If are generally a frustrated inventor, you can cut mechanical parts for prototypes, within the range of materials including wood, plastics, aluminum, composite materials like carbon fiber laminate, or printed circuit board subject matter.

These machines are basically computer directed. All you have to do is download the program onto the machine, set the machine up a concern . right tools and then press start off button. Handy will take care of the rest for shoppers. It will continue to turn that chair leg program tells it to stop. You can be assured that as it does stop, the machine has created piece perform that in order to the right specifications.

The 3D CNC Router offers more carving, improvements and design options. Designing and a lot more tool-path creation is two different things completely presently there are different software programs for for each. You must learn how to part ways the both.

So, the mold maker gets the steel the brand new shapes, and puts them in a holder (mold base), and makes everything fit perfectly so the plastic part comes out nice and clean. If he does a poor job, observing see the little ugly lines on the part, or little fins of plastic sticking out, like wonderful see on a cheap Chinese toy.

The control computer has got control software loaded on face value. You start up the control software then load within the CNC Program you fashioned. When you do this, the G-Code will be visible and able to go. Whenever you prep your CNC Machine and zero it out, you can begin your “cycle.” A cycle is usually completing one CNC Program, which can be a machining set. You will also hear the term “Cycle Time” on the professional side of CNC a much more. The quicker you can get the cycle time, the more parts you may make. And yes, that translates to more income.